When working on your plumbing system, understanding the various types of fittings available can greatly enhance your project’s success.

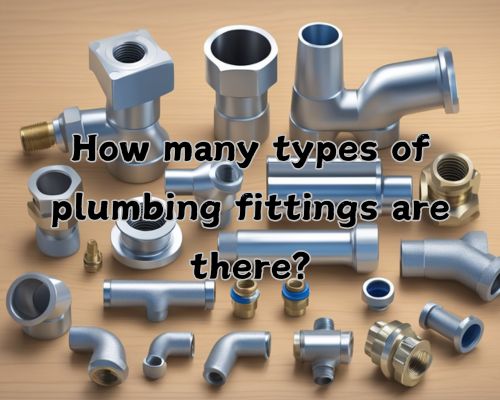

There are around 20 different types of plumbing fittings that cater to needs such as water supply, drainage, and ventilation.

These fittings, including elbows, tees, and couplings, come in multiple materials like brass, PVC, and cast iron, making them versatile for different applications.

Water supply systems often rely on fittings such as pipe nipples and hexagon nipples. These fittings connect pipes to appliances or extend pipe runs.

Meanwhile, drainage systems make extensive use of fittings like elbows and wyes, ensuring efficient fluid flow and reducing clogs.

Ventilation systems utilise specialised fittings to maintain proper air circulation within plumbing systems.

Based on Plumber Warragul, selecting the right type of plumbing fitting is crucial for ensuring the efficiency and durability of your plumbing system.

Different materials and designs are available to address specific needs and challenges you might face.

From withstanding high pressure in water supply lines to resisting corrosion in drainage pipes, each fitting plays a vital role in maintaining a robust and reliable system.

Types and Applications of Plumbing Fittings

Plumbing fittings come in various types and materials, each designed to perform specific functions within plumbing systems. This section explores the different materials used in plumbing fittings, their functions, and specialised fittings for control and connection.

Common Materials and their Properties

Plumbing fittings are made from a variety of materials, each chosen based on its properties and suitability for different applications.

Copper fittings are corrosion-resistant and have excellent thermal conductivity, making them ideal for hot water systems.

PVC and CPVC fittings are lightweight, easy to install, and resistant to chemicals, often used in cold and hot water supply lines.

Stainless steel and carbon steel fittings are known for their strength and durability, suitable for high-pressure applications.

Meanwhile, brass fittings offer good malleability and corrosion resistance, commonly used in water supply lines.

ABS plastic fittings are used mainly in drainage and waste systems due to their rigidness and impact resistance.

Every material has unique properties that make them suitable for specific plumbing jobs.

Fitting Types and Functions

Different types of fittings serve various purposes in plumbing systems.

Elbow fittings change the direction of pipes, useful in navigating around obstacles.

Tee fittings allow branch connections in plumbing lines, enabling multi-directional fluid flow.

Coupling fittings join two pipes of the same diameter, while reducers connect pipes of different diameters.

Adapters and unions make transitions between different pipe materials or sizes easier.

Finally, caps and plugs seal the ends of pipes, preventing leaks.

Nipple fittings, including hexagon and swage nipples, connect straight pipes or adapt changes in direction and diameter.

Each fitting type is essential in creating an efficient and leak-free plumbing system.

Specialised Fittings for Control and Connection

Specialised fittings offer control and specific connections in plumbing systems.

Valve fittings such as check valves prevent backflow, safeguarding water quality.

Meanwhile, barb fittings secure hoses in irrigation and ventilation systems, providing a tight seal.

Cross fittings connect four pipe sections at right angles, ideal for complex plumbing arrangements.

Also, flanges provide sturdy pipe connections in high-pressure systems.

Lastly, wye fittings join three pipes for efficient waste water drainage, while union fittings allow easy disconnection for maintenance.

Each specialised fitting is designed to optimise the plumbing system’s performance and reliability, ensuring functionality and safety.

Installation and Maintenance Considerations

Proper installation and maintenance of plumbing fittings are crucial to ensure a leak-free and efficient plumbing system. With Plumber Warragul, this section covers the different methods for connecting and sealing pipes, as well as how to troubleshoot common issues that may arise.

Connection Methods and Sealing Techniques

Several methods are available for connecting plumbing fittings, each with its own advantages.

For example, threaded connections are common, using male and female ends to secure a tight fit.

On the other hand, compression fittings utilise a nut and ferrule to seal the connection, ideal for water supply lines.

Meanwhile, slip fittings are handy for easily disconnecting and tightening connections.

Welding techniques are often used for metal pipes, ensuring a strong and durable seal.

In plumbing projects involving copper pipes, soldering using a lead-free solder offers a reliable leak-free joint.

The quality of the seal directly impacts the system’s longevity, so always ensure fittings are properly installed to avoid corrosion and leaks.

Troubleshooting Common Issues

When dealing with plumbing fittings, you might encounter common issues such as leaks or corrosion.

Inspect connections if you notice a drop in water pressure. This can signal a faulty seal or blockage.

One common problem is leaking threaded connections. You can often resolve this by applying thread seal tape or re-tightening the fitting.

Corrosion, particularly in metal pipes, can weaken seals and connections.

Address this by periodically inspecting fittings and replacing any corroded parts.

For blockages, especially in drainage and ventilation systems, ensure proper venting to maintain water flow.

In cases of persistent issues, replacing components such as check valves, elbows, and tees might be necessary to restore functionality.